Polymer solution preparation Technology

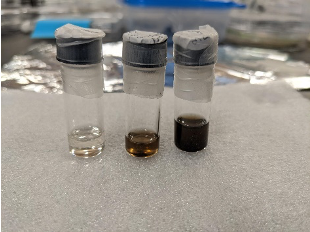

Highly controlled and homogenously dispersed polymer nanoparticle solutions are prepared using sophisticated mixing techniques. KRG research lab uses several ultrasonication technologies for homogenously dispersing nanoparticles in polymer solution. Polymer solutions are prepared using two different sonication process-

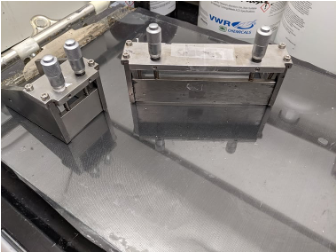

- Bath sonication (VWR ultrasonic cleaner)

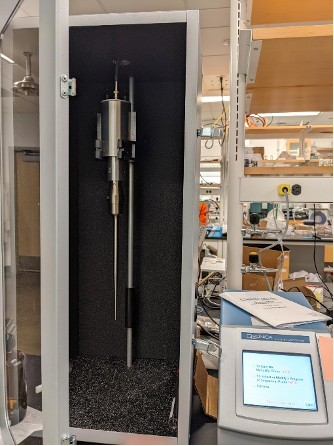

- Probe sonication (Qsonica Q700)

Bath sonication is used as a primary step to disperse the nanoparticles in the polymer solution. Ultrasonic baths create ultrasonic waves in the tanked water to aggressively agitate the nanoparticles and suppress the coagulations. Ultrasonication using high frequency sound waves is highly effective and efficient to prevent the nanoparticles from aggregating.

The probe sonicator is used to finally sonicate the polymer solution just before casting the film. We have Q700 sonicator which is the most technologically advanced sonicator available today. The Q700 is the only sonicator on the market that offers full amplitude control from 1-100%. This enables greater control of the probe’s intensity, helping to pinpoint the optimum settings for efficient sample processing.

Polymer Film preparation Technology

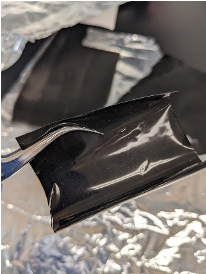

KRG lab has several film preparation facilities. Films prepared in our lab are in the thickness range of nanometer to centimeter.

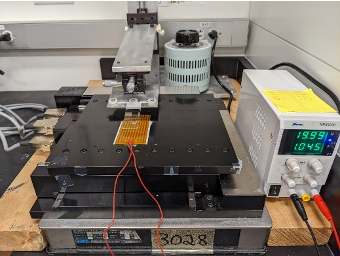

Flow coater and spin coater are used for nanometer range thickness films. During the coating process we are able to heat the substrate using a highly temperature controlled heated stage. The film preparation techniques are reproducible which is precisely controlled by the speed of the stage. We also use doctor blade and drop casting for thicker film preparation.

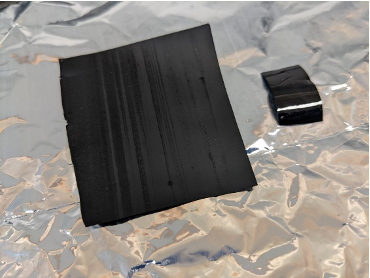

KRG lab has successfully overcame the challenge of adhering low surface energy polymer layers to physically bond together by introducing sophisticated adhesion techniques.

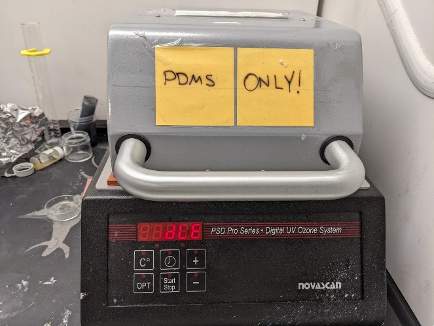

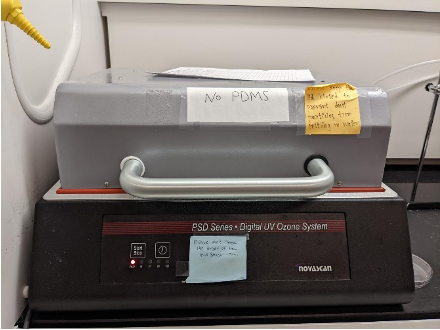

We have two different PSD-UV – Benchtop UV-Ozone Cleaner for different polymer systems which ensures contamination free substrates to begin with. A mercury vapor lamp generates ultra-violet light and ozone resulting in the atomic cleaning of silicon, silicon nitride, glass, metals, ceramics and other materials. The PSD and PSDP can also be used for UV curing, UV patterning, sharpening AFM probes, ozone etching and more.

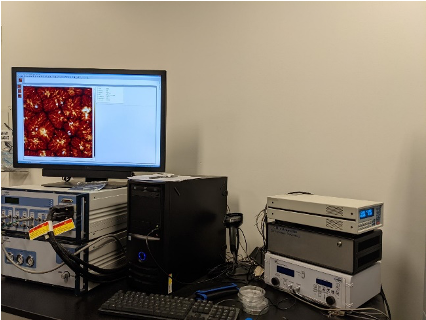

Surface Characterization technology: (AFM)

We have Brucker Dimension Icon with Scan asyst, World’s highest performance large-sample AFM in our lab for intricate surface morphology analysis. It has 90 micron scan range system, surpassing the open-loop noise levels of high-resolution AFMs.

EMI Characterization technology:

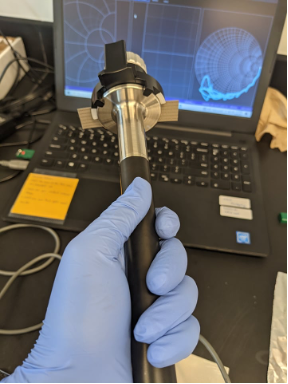

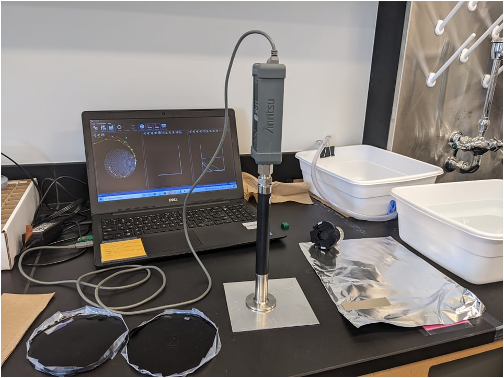

Near Field Analysis technique for EMI shielding: (Coaxial Transmission Line Test)

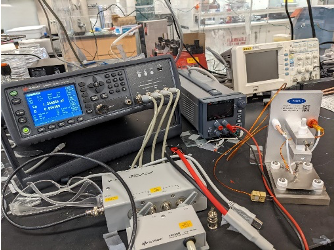

- ShockLine™ 1-Port USB

Vector Network Analyzers

MS46121A

150 kHz to 6 GHz - : 4 MHz – 3 GHz, with integrated vector reflectometer model R60 from Copper Mountain Technologies.

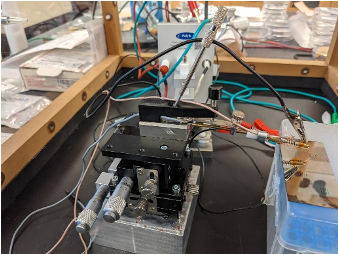

SPEAG’s Dielectric Assessment Kit (DAK) product line offers high-precision dielectric parameter measurements (permittivity, conductivity, loss tangent) over the very broad frequency range from 4 MHz to 67 GHz for various applications in the electronic, chemical, food, and medical industries. The probe is connected to a vector network analyser (VNA) for measurement of the complex reflection coefficient (S11) at the probe end. The measured S11 is then converted into the complex permittivity of the material under test using the DAK software.

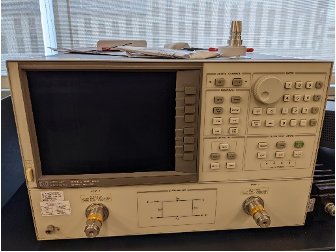

8720C Microwave Network Analyzer (50 MHz and up to 20 GHz):

The Keysight 8720C vector network analyzer characterizes RF and microwave components down to 50 MHz and up to 20 GHz. Fast-sweeping built-in synthesized source with optional 1 Hz frequency resolution. It has two independent display channels for simultaneous measurement of reflection and transmission characteristics.

E4980AL Precision LCR Meter 20 Hz to 1MHz

KRG la bis capable of extracting electric permittivity data from the capacitance and loss tangent value directly provided by the LCR meter. Offering fast measurement speed and outstanding performance at both low and high impedance ranges, the E4980AL is the basic tool for general research and development and manufacturing test of components and materials.

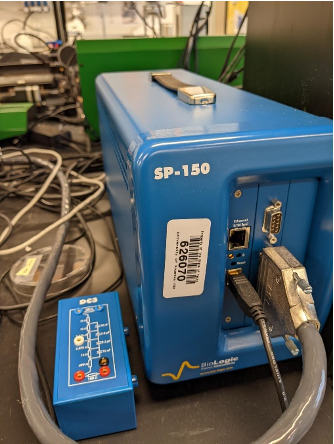

Biologic SP-150 Potentiostat for impedence measurement.

AC conductivity is mainly determined by processing Impedance data obtained by impedance spectroscopy measurement. Thus, an impedance analyzer with a large frequency range is needed to investigate the conduction mechanisms of different kinds of polymer. For the purpose of illustration, the through-plane AC conductivity of Yttria Stabilized Zirconia electrolyte, used as a solid electrolyte material for SOFC, was investigated by Impedance spectroscopy at high temperatures (from 600 °C to 900 °C) using an integrated solution, consisting of an impedance analyzer, a high temperature furnace and a high temperature sample holder.

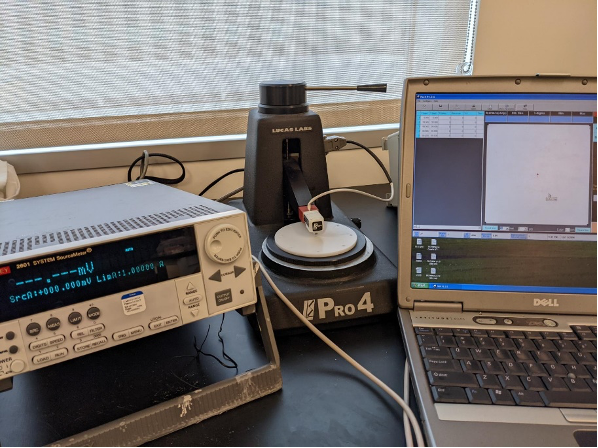

For sheet and bulk resistivity measurements on thin polymer film, we have Pro-4 Four Point Resistivity Systems. Proper use of the standards and the calibration procedure insures the specified system accuracy of better than 1%. The standard range of the system is 1 miliohm up to 800K ohms-per-square.